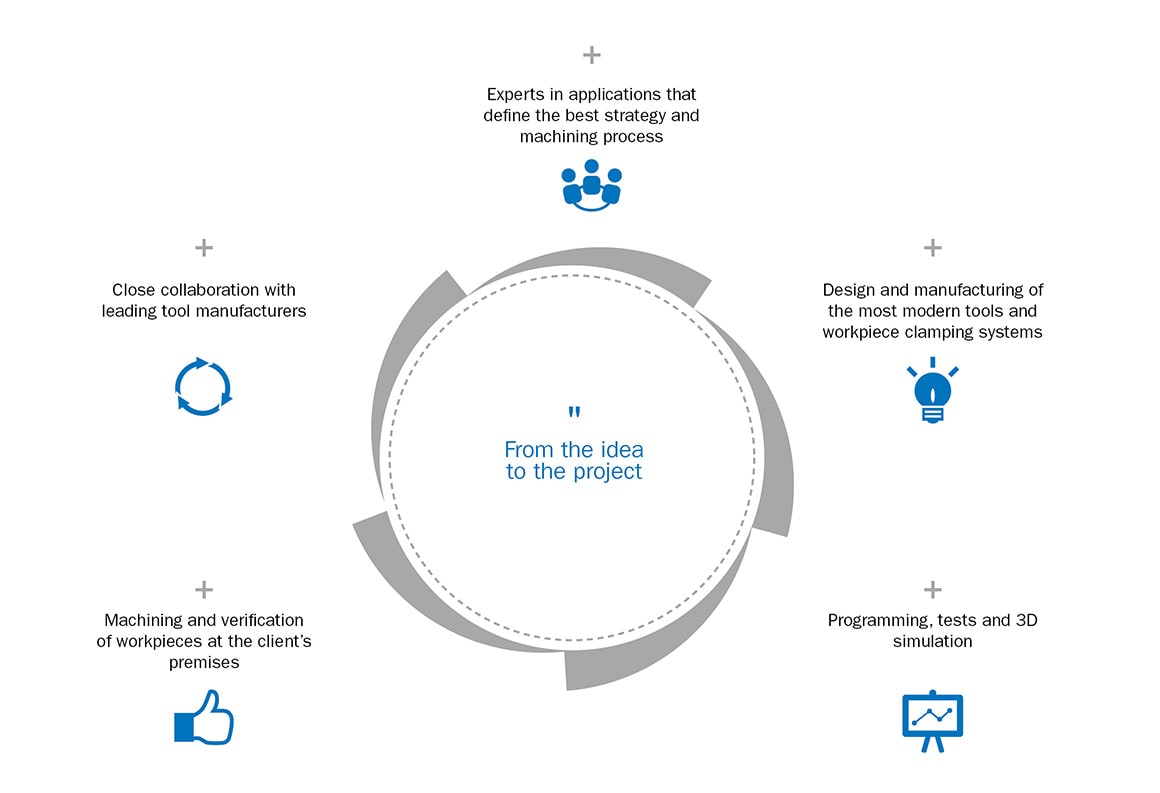

SORALUCE offers professional advice in machining engineering with a team of highly experienced engineers who evaluate the production and machining process of our clients and provide solutions to optimise them.

- Increased profitability

- Enhanced productivity

- Reduced cycle times

- Use of new tools

- Competitive advantages with advanced technology

Machining studies

Detailed studies of machining processes to offer solutions for the technical and financial requirements provided by the client.

- Global analysis of the production process

- Process engineering

- Definition of machining process

- Simulation of the machining process

- Installation requirements

- Automation specifications

Machining cycles

Design and development of particular cycles for specific machining tasks.

- Development of new cycles

- Customised Control System software to manage the machining cell using the job list concept for automated solutions

Tools and fixtures

The best tools and fixture solutions (design and/or manufacture) based on our experience and close collaboration with the main suppliers and clients.

- Equipment specifications

- Design, manufacturing of the fixtures

- Tool selection

Production assistance

Production assistance during the first weeks and/ or workpieces.

- Support during production

- Operation reports

- Personalised training

- Equipment monitoring

- Process auditing

Machining tests

Machining tests during the pre-acceptance and final acceptance of the machine.

- Initial workpiece machining

Turnkey projects

A complete turnkey solution service including tools and fixtures, CNC programming, simulation and production assistance and system integration.