SORALUCE´s maintenance programmes help to prolong the life of your machine and keep it in perfect working order.

- Optimum availability

- Guaranteed precision

- Preventing machine stoppages

Preventive maintenance

Regular preventive maintenance according to a check-list drawn up for each machine model or project.

- Checking protocols for all items

- Replacement of filters & other consumables as required

- Report on system status and functionality and on any measures needed to keep it running optimally

- Detailed inspection results report

- Corrective actions required

Geometric maintenance

- Adjustment of the geometry of the machine, table & heads in case of deviation

- Alignment of head articulations

- Geometrical precision. Laser interferometer & ball bar

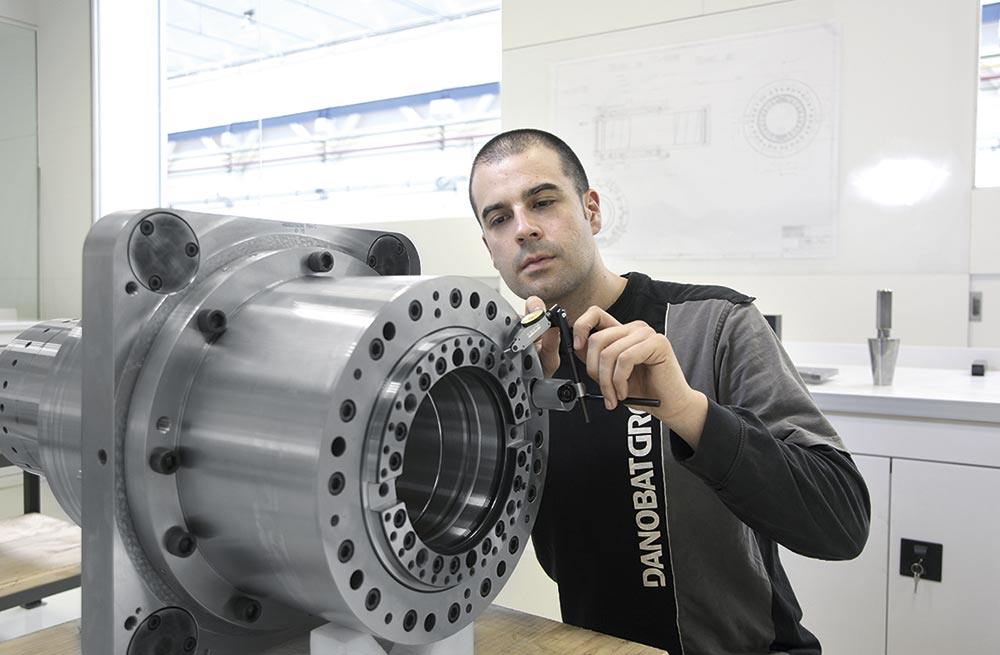

Head maintenance

- Preventive head maintenance

- Repair service

- Temporary head replacement during repairs