Soraluce Quality Innovation Award Winner

The Soraluce DWS – Dynamic Workpiece Stabiliser – System takes the award.

- The Quality Innovation Award jury for the Basque Country stage has selected Soraluce as the winner in the large company category for the DWS - Dynamic Workpiece Stabiliser – System.

- Soraluce will now compete as a finalist in the international stage of the Quality Innovation Award, whose ceremony will be held in Belgrade (Serbia) on 4 February 2021.

- Already in 2015 Soraluce won the international Quality Innovation Award for its innovative DAS® System, which reduces the risk of chatter during the machining process and thus improves the cutting capacity of the machine by up to 300%.

The Quality Innovation of the Year competition was created in Finland in 2007 to stimulate the emergence and development of organisational, process and product innovations, etc. The participating countries include Sweden, Lithuania, Latvia, Estonia, Hungary, Israel and the Basque Country, through Euskalit.

The EUSKALIT Quality Innovation Award team, experts in different knowledge areas identified by UNIBASQ, found that the innovation of Soraluce’s entry in the large company category stood out in the five aspects assessed in the process: novelty, utility, learning, customer orientation and effectiveness.

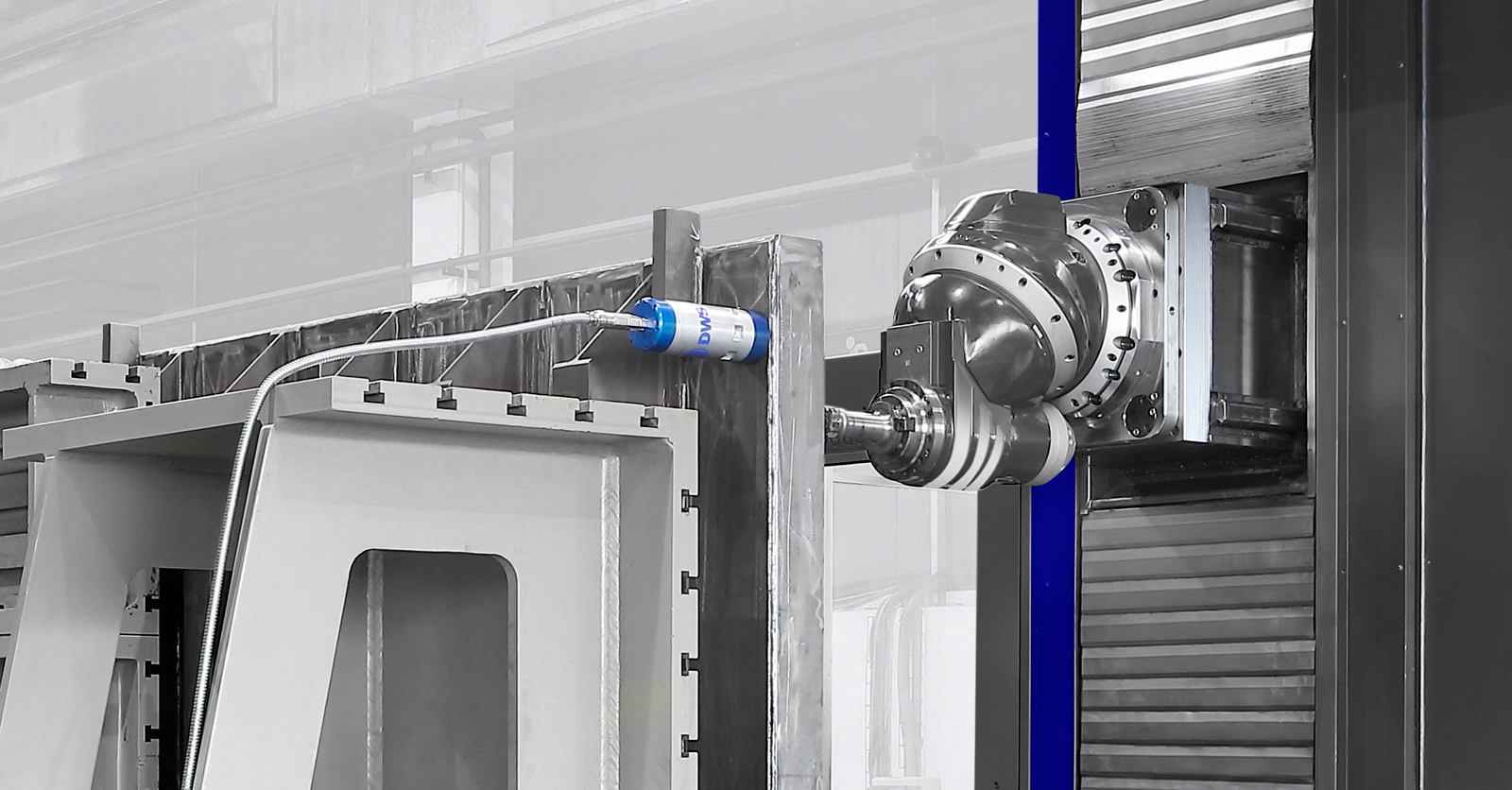

Soraluce has received this award for the innovative DWS – Dynamic Workpiece Stabiliser. This patented system eliminates the chatter which usually occurs when flexible workpieces are being machined. The DWS is an active damping device which consists of a controller and one or more inertial actuators placed over the workpiece to be machined.

One its main benefits is a better surface finish in areas where the workpiece is more flexible, along with the chance to boost productivity thanks to in-depth passes with no vibration problems. Its user friendliness, its adaptability to different workpieces and its portability are some of the other advantages of the device.

The DWS, a ground-breaking development on the market, provides an effective solution for the problems associated with machining slim-format workpieces. It is an improvement on traditional alternatives such as the designing of costly special tooling, or less reliable and less effective solutions.

Soraluce, along with its technological centre, has developed different solutions to eliminate chatter and, therefore, to increase the cutting capacity of the equipment and make the machining processes more efficient. This is a field where the company has successfully been focusing for several years and has received prestigious awards in recognition of that work.

The award ceremony will take place during the Advanced Management Gala in December.

This is a further step in consolidating Soraluce’s prestige as a technological leader in the milling sector, where innovation arises from and for its customers, in order to meet their needs and produce developments that are fully in line with the manufacturing challenges that the customer have to face.