High stock removal capacity and precision finishing, hallmarks of the new SORALUCE PMG 6000

Weiß Metallbau GmbH is located in Neuenstadt-Stein, Germany. The company is a global leader in the manufacture of moulds and tools, mostly prototypes and pre-series parts, for the automotive industry.

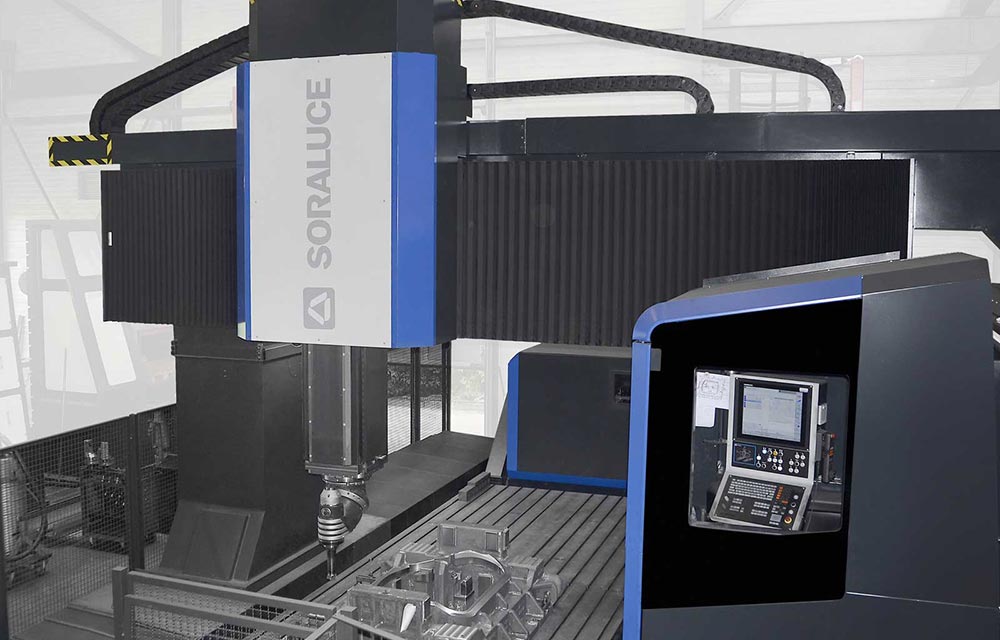

Weiß Metallbau already owns 10 Soraluce milling machines. Weiß Metallbau´s company strategy is one of growth through providing innovative solutions to the requirements of exacting customers, with the aim of achieving the best result for each application. In support of this strategy, the company has decided to depend on Soraluce to supply a SORALUCE PMG 6000 portal milling machine.

Soraluce has recently presented its new range of portal machines for machining large components, demonstrating once again its leadership and technological capability.

Soraluce´s new portal range is yet another example of the company´s continual evolution. The line is being introduced as a complement to the other products in the range of milling machines. It is backed by Soraluce´s knowledge and experience in milling and turning technologies, as the company is a technological leader in the sector. Soraluce presents a complete range of portal machines in two architectures: gantry type machines and mobile table machines, including fixed and mobile crossbeam alternatives, configurable with a range of heads and other options. Soraluce develops technological solutions that respond to a wide variety of customer requirements, driving efficiency and productivity to the maximum.

The new family of gantry machines offers a range of high-capacity, high-precision machines, with high stock removal rate, incorporating the most advanced damping systems on the market (such as DAS®) and providing great versatility thanks to the multitasking milling, turning and grinding capacity. These are machines that can be customised to the customer´s requirements, in terms of milling and turning heads, tool magazines and work areas.

To achieve this, Soraluce has invested €9 million in the purchase and adaptation of its facilities, with a new 4,900 m2 warehouse (140 metres long x 35 metres wide x 17 metres high) for the assembly of these machines. This is the new PORTAL FACTORY, the most modern, complete and advanced manufacturing centre dedicated to the manufacture of portal machines. The installations are exclusively focused on this type of machine, and all the assembly and validation activities of each machine produced are carried out here.

The SORALUCE PMG 6000 machine purchased by the customer Weiß Metallbau is a gantry-type portal machine with a longitudinal traverse of 6,000 mm, a cross traverse of 4,500 mm and a vertical traverse of 1,500 mm, equipped with an automatic stepless head with 0.001º x 0.001º rotation, at 7,000 rpm, 37 kW, 1,220 Nm and a direct horizontal head of 60 kW, 4,000 rpm, 1,750 Nm. In addition, the machine is prepared to incorporate the customer´s electro-spindle. It also has an automatic head-changer and pick-up for three heads.

Soraluce has been a pioneer in the use of linear guidance systems and has applied all of its knowledge to the development of the new portal machines, combining guidance technology with passive damping systems, through the inclusion of damping pads as well as active systems, such as the DAS® (Patented) system, exclusive to Soraluce. This results in incredibly accurate machines which are highly dynamic, stable during machining and reliable in terms of availability.

When the travel systems were selected to drive the different axes, priority was given to durability and reliability. The transverse and longitudinal axes are driven by double rack and pinion systems by means of two motors configured in master-slave mode on each of the racks. This guarantees that transmission is highly dynamic (with maximum speeds of 35 m/min), free of backlash and wear-resistant.

There are several options for the motor to drive the head. These alternatives are integrated in the ram and always cooled by water. The most powerful variants can also incorporate the option of mechanical reduction. The machine supplied to Weiß Metallbau includes a direct motor of 60 kW and 900 Nm nominal.

The operator´s cabin is fully enclosed and includes the CNC panel for smooth movements. It enables perfect visibility of the machining area.

In general, these are highly configurable machines and it is possible to work in one or several areas of them, be it to maximise productivity, to minimise stoppages while a part is being positioned or to increase the versatility and flexibility of the machine, including rotary tables for milling and turning.

The machine is equipped with Soraluce´s Data System monitoring platform. In the user´s working environment, the Data System displays information on alarm management, machine usage, energy consumption and machine maintenance.