SORALUCE SA Fixed table travelling column milling machine

Performance Line. Born Reliable. Born Flexible.

- Proven quality components: high performance 7000 rpm heads, direct drive inline motor and robust software.

- Best geometric stability through water-based cooling and real time thermal compensation.

- Solutions adapted to your needs: New choice of milling heads with higher spindle speed and easy integration of milling & turning tables (Rotary milling / turning table size: Ø 1000 mm / Max. swing: Ø 1500 mm).

- Set & Go: Less footprint in the workshop. Less expensive foundation. Easy transport & installation.

- Ergonomics & Easy maintenance.

|

Characteristics |

SA40 |

SA50 |

SA60 | |

|---|---|---|---|---|

|

Table area |

mm |

4000 x 1000 |

5000 x 1000 |

6000 x 1000 |

|

Longitudinal traverse "X" axis |

mm |

4000 |

5000 |

6000 |

|

Vertical traverse “Z” axis |

mm |

1500 |

||

|

Cross traverse “Y” axis |

mm |

1200 |

||

|

Spindle power |

kW |

32 (S1) |

||

|

Spindle speed range |

min-1 |

6000 / 7000 |

||

|

Rapid traverse |

mm/min |

35000 |

||

|

Tool magazine |

No. tools |

40 / 40+24 |

||

Customisation

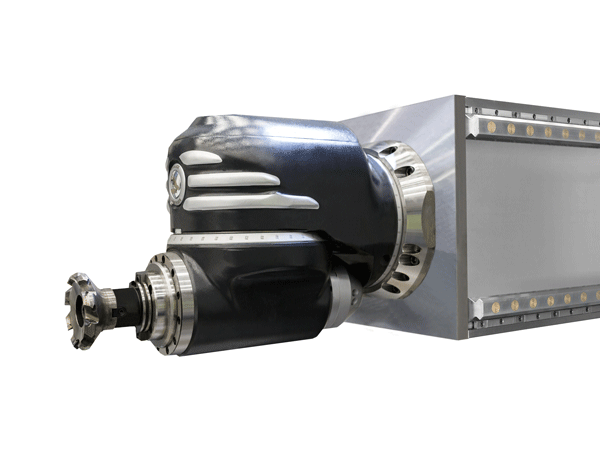

Select your head:

Technical data

It enables for:

- Automatic indexing of vertical and diagonal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 43 / 46 / 55 kW

- 2.5° x 2.5° / 1° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 / 6000 / 7000 min-1

Technical data

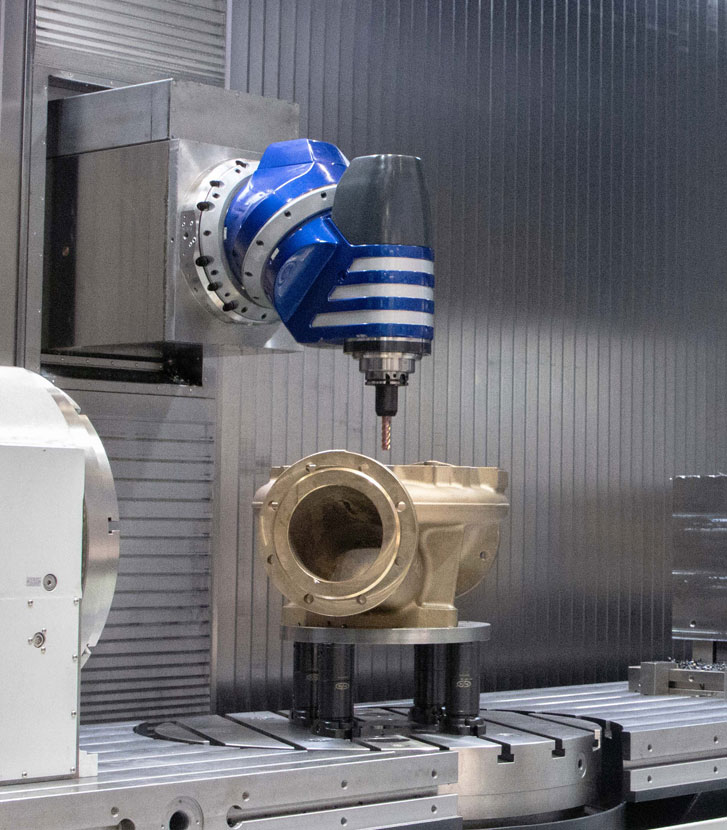

Its compact design is specially conceived for machines with an in-line motor. It allows the simultaneous positioning of both head articulations, reducing non-production time.

Inverse machining capability:

- Up to -45º

- No additional setups

- Improved cycle time

- Better finishing quality

- Minimum manipulation

- Full advantage of machine travel

- No need for additional work piece support fixtures

- Close to table head spindle accessibility for both front and lateral milling

- 37 / 43 kW

- 1º x 1º

- 4000 min-1