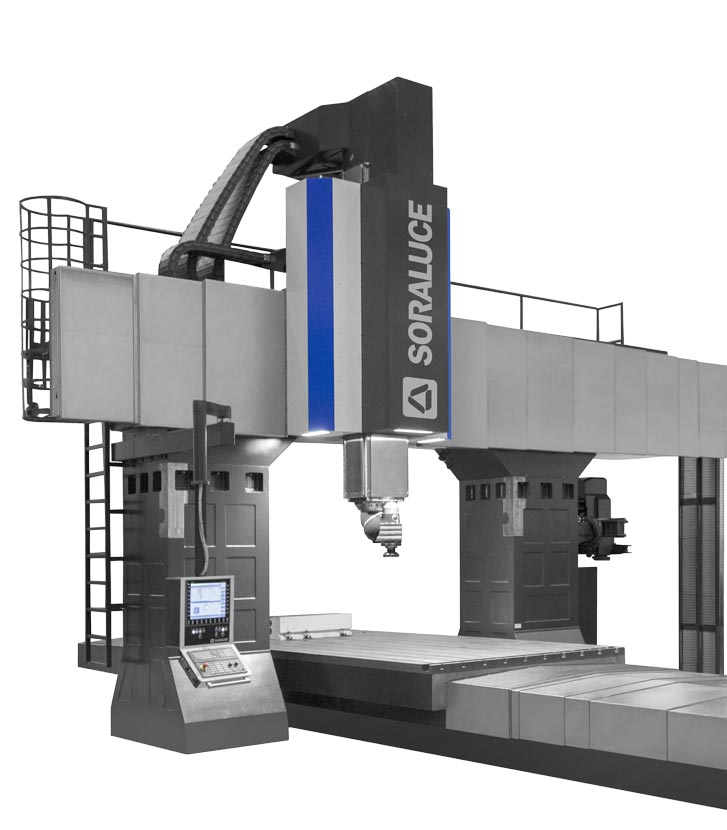

PM Portal Mobile table multitasking Machine - SORALUCE

- High precision and enhanced productivity for large size components.

- Advanced SORALUCE technology geared towards maximising productivity, precision and customisation: DAS system, Modular Quill, Vertical Ram Balance, Accura Heads, SSV and Adaptive Control.

- SORALUCE head technology: a highly reliable, extensive range of SORALUCE quills and heads

- Automatic head and tool changing systems

- SORALUCE Digital, Data System: a comprehensive monitoring package with continuous information of machine and process status

- Precise and efficient machining results

- Excellent dynamics thanks to the rapid travel of the axes

- High power and torque for high performance machining

- Improved stability to enable high stock removal for prismatic components in a single set-up belonging to the mechanical engineering, energy and capital goods industries

- One or two operator’s platforms with their respective control panels, thus allowing the best location of the operator in each operation

- Total machine concept design: a complete working area analysed for optimal comfort, safety and ergonomics (maintenance spots, operator area)

|

Characteristics |

PM | |

|---|---|---|

|

Table length & width |

mm |

Length: 5000 / 6000 / 7000 - Width: 2500 / 3000 |

|

Longitudinal traverse “X” axis |

mm |

5600 / 6600 / 7600 |

|

Cross traverse "Y" axis |

mm |

4000 / 4500 |

|

Vertical traverse Ram "Z axis" |

mm |

1500 / 2000 |

|

Vertical traverse Cross beam "W" |

mm |

1000 / 1500 / 2000 |

|

Spindle power |

kW |

43 / 60 |

|

Spindle speed range |

min-1 |

Up to 7000 |

|

Rapid traverse |

mm/min-1 |

X = 30000 Y/Z = 35000 |

|

Tool magazine |

No. tools |

40 / 60 / 80 / 100 / 120 |

Customisation

Select your head:

Technical data

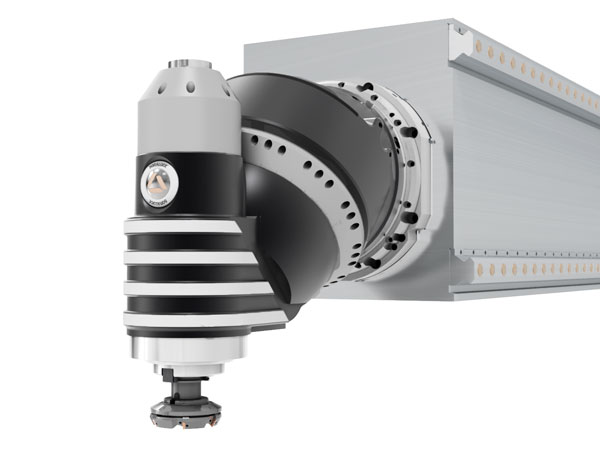

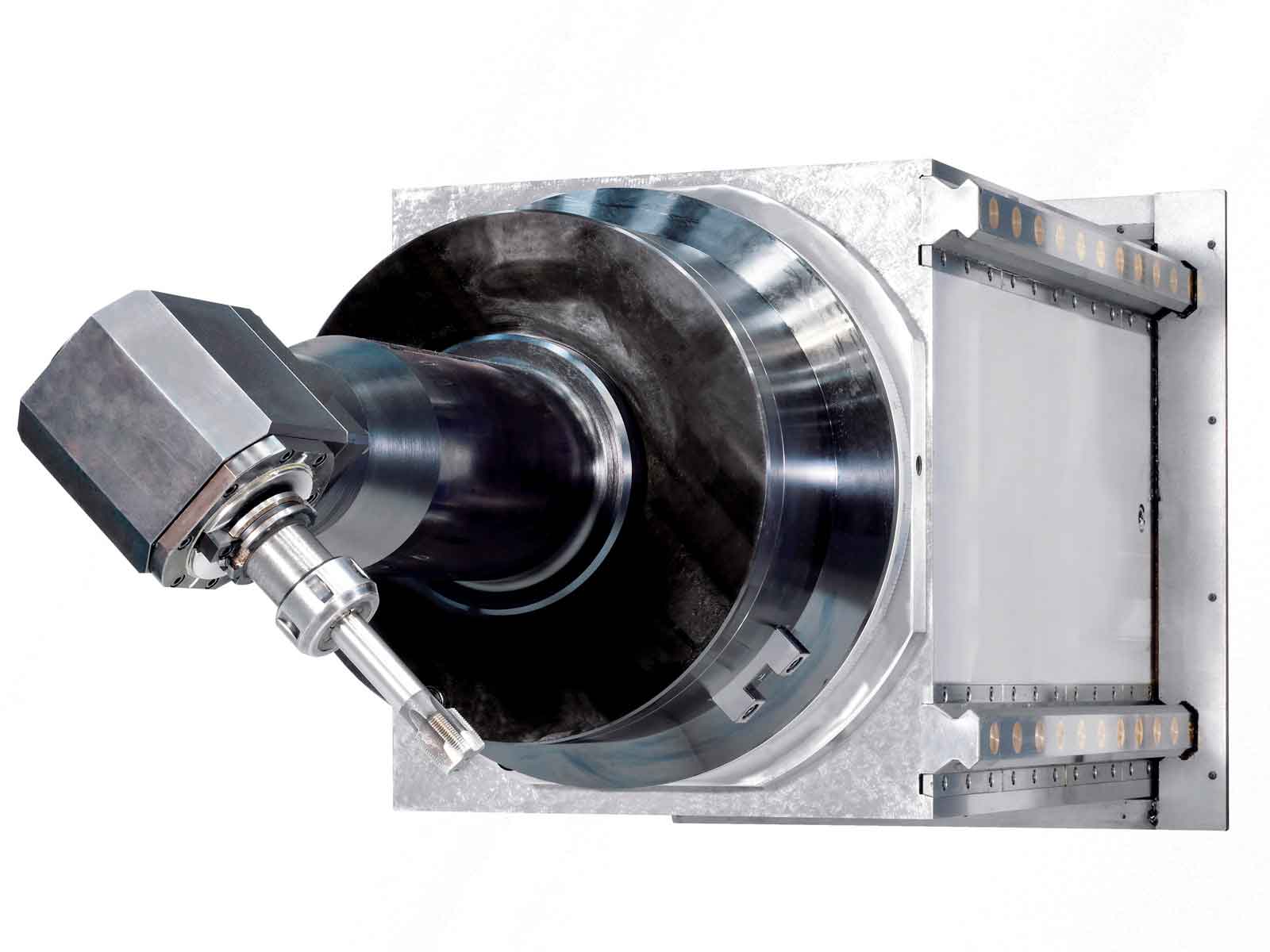

- 5-axis continuous indexing head, indexing at 0,001ºx0,001º

- Full 5 axis machining or use for fast positioning

- Automatic tool changing.

- Automatic head changing

- Cooling through the spindle

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- Spindle locking option (turning operations)

- Available for Soraluce FP, FR and FXR models

- 37 kW

- 0.001° x 0.001°

- 7000 min-1

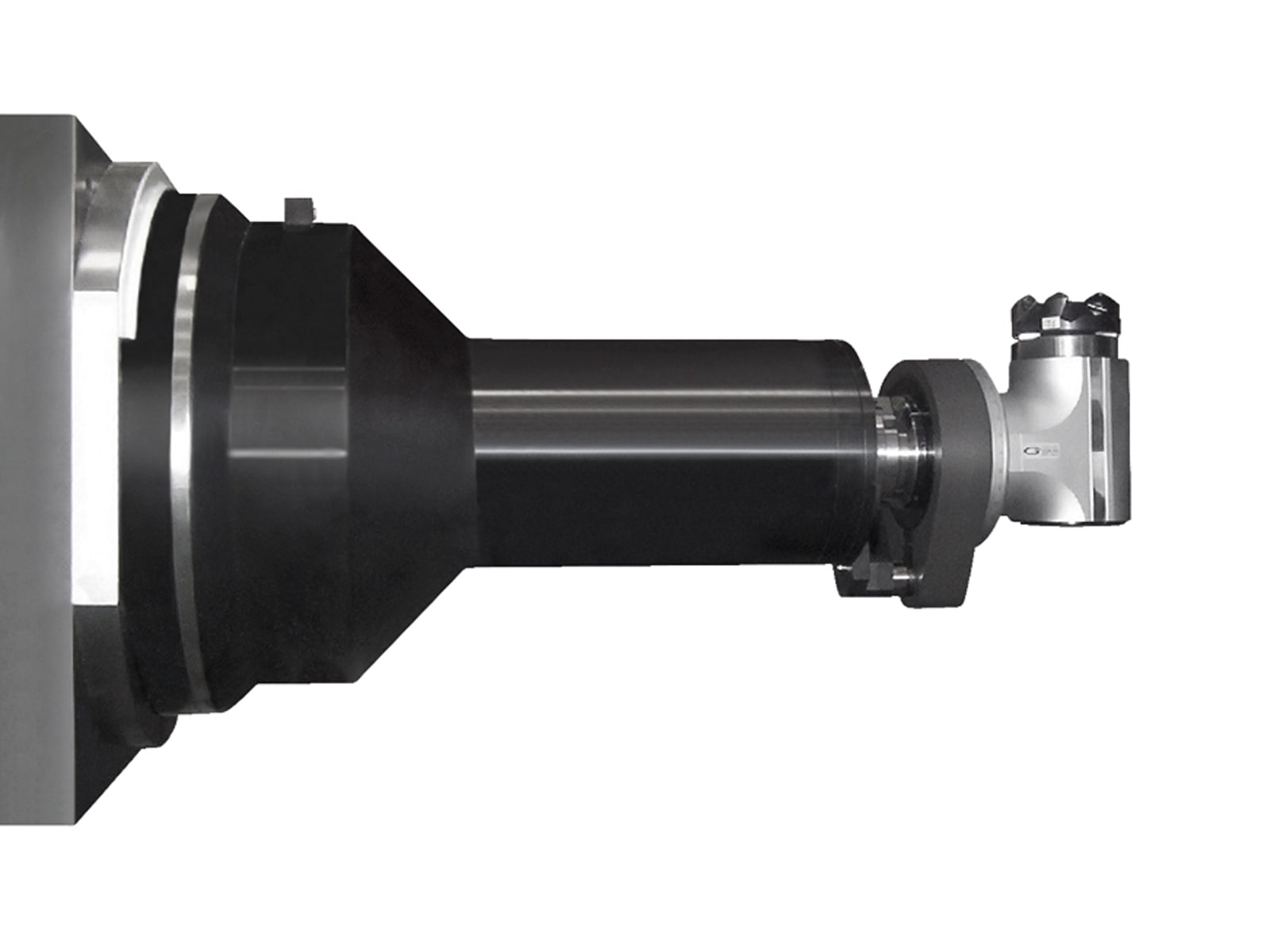

Technical data

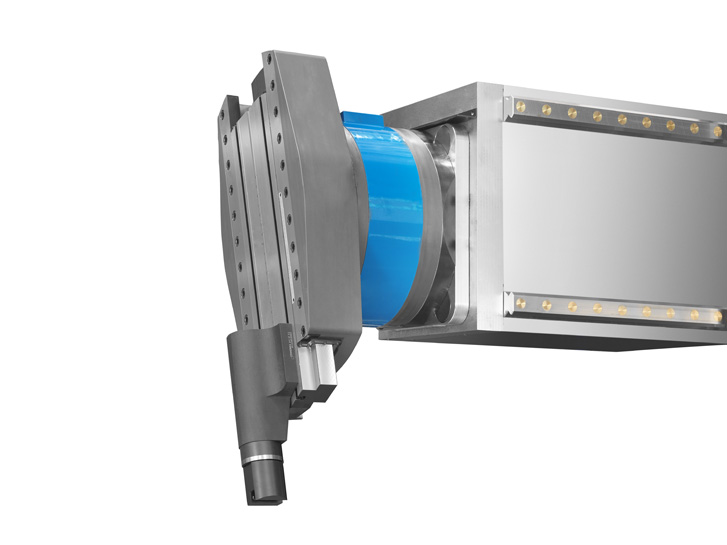

It enables for:

- Automatic indexing of vertical and diagonal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 43 / 46 / 55 kW

- 2.5° x 2.5° / 1° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 / 6000 / 7000 min-1

Technical data

It enables for:

- Automatic indexing of vertical and horizontal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 37 / 43 / 46 kW

- 1º x 1º

- 5000 / 6000 / 7000 min-1

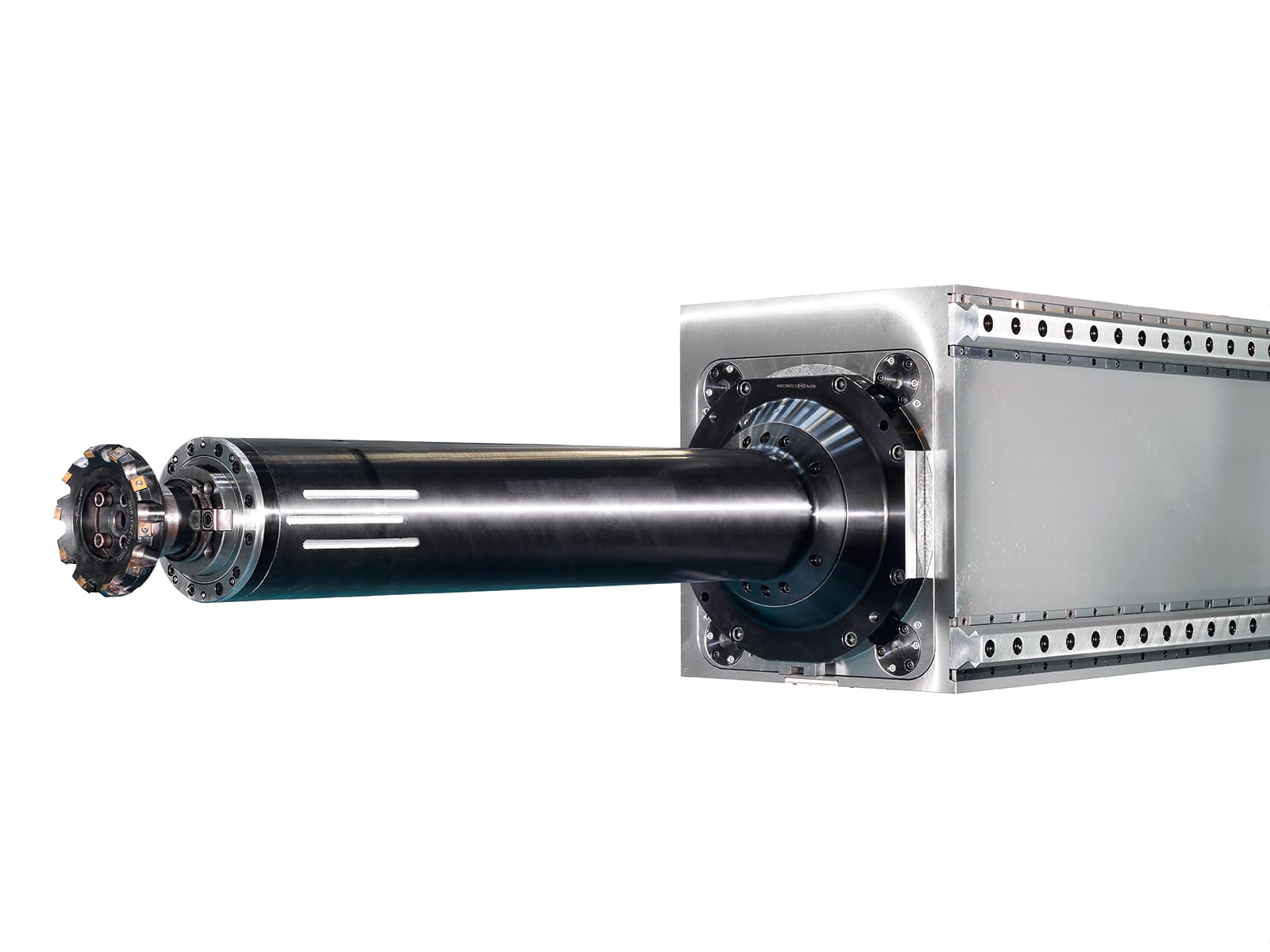

Technical data

It enables for:

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system (no external tubes exposed to chips).

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- Flexibility

- Interchangeability

- Options

- C Axis

- Maintainability

- 43 / 46 / 49 / 81 / 106 kW

- 2000 / 3000 / 4000 / 5000 min-1

Technical data

- Special angular heads (railway bogie, motor block, etc.).

- Special adaptors

Technical data

- NC Facing heads

- Angular heads

- 5 axis heads

- Electrospindles

Technical data

- Heavy duty angular head

- Angular and horizontal extensions

- Turning adaptors

- O&G oriented heads

- Rotary couplings