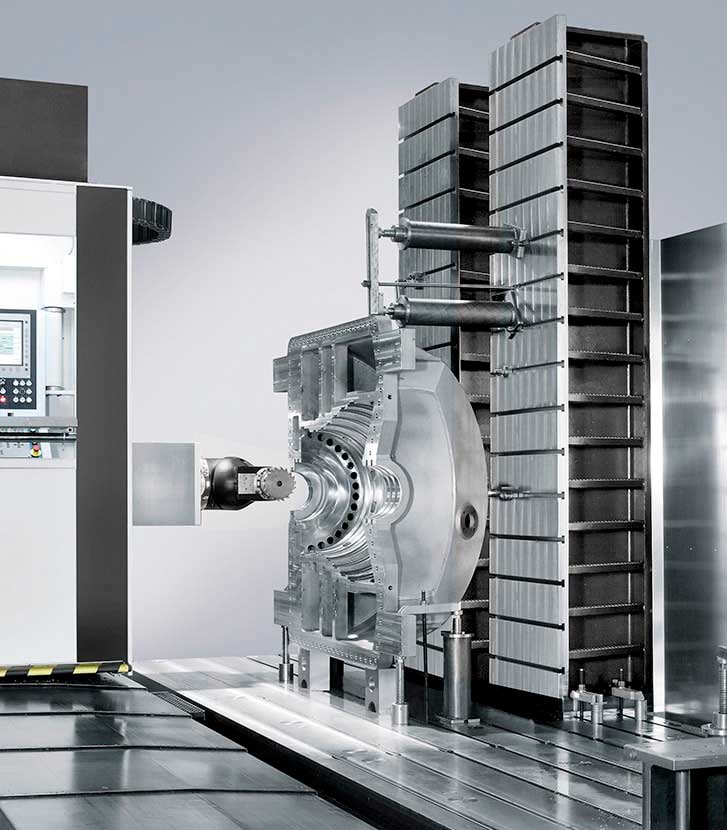

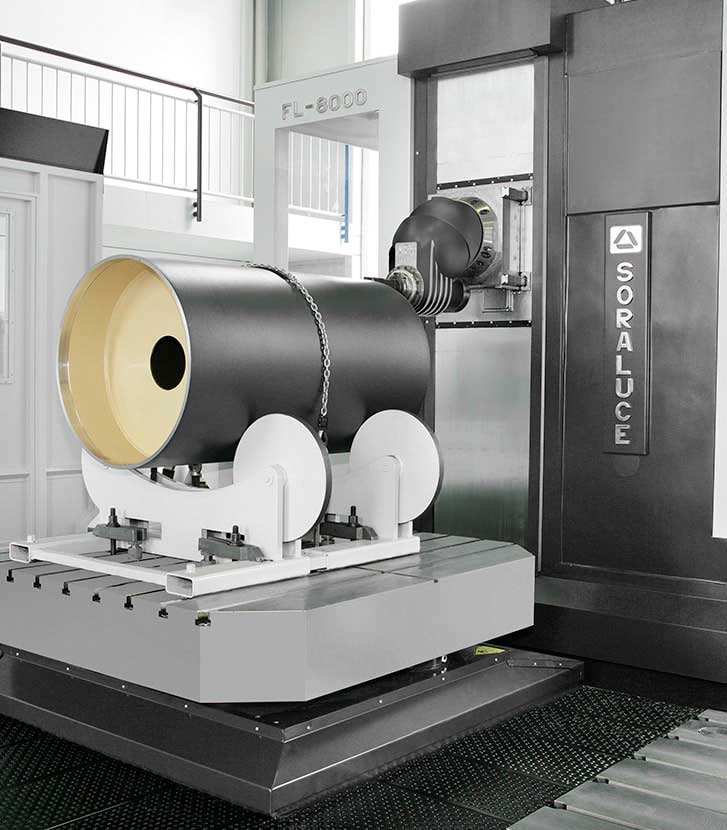

SORALUCE FLP floor type milling boring machine

- Improved flexibility and high dynamics for enhanced performance.

- Advanced SORALUCE technology geared towards maximising productivity, precision and customisation: DAS system, Accura Heads, SSV and Adaptive Control.

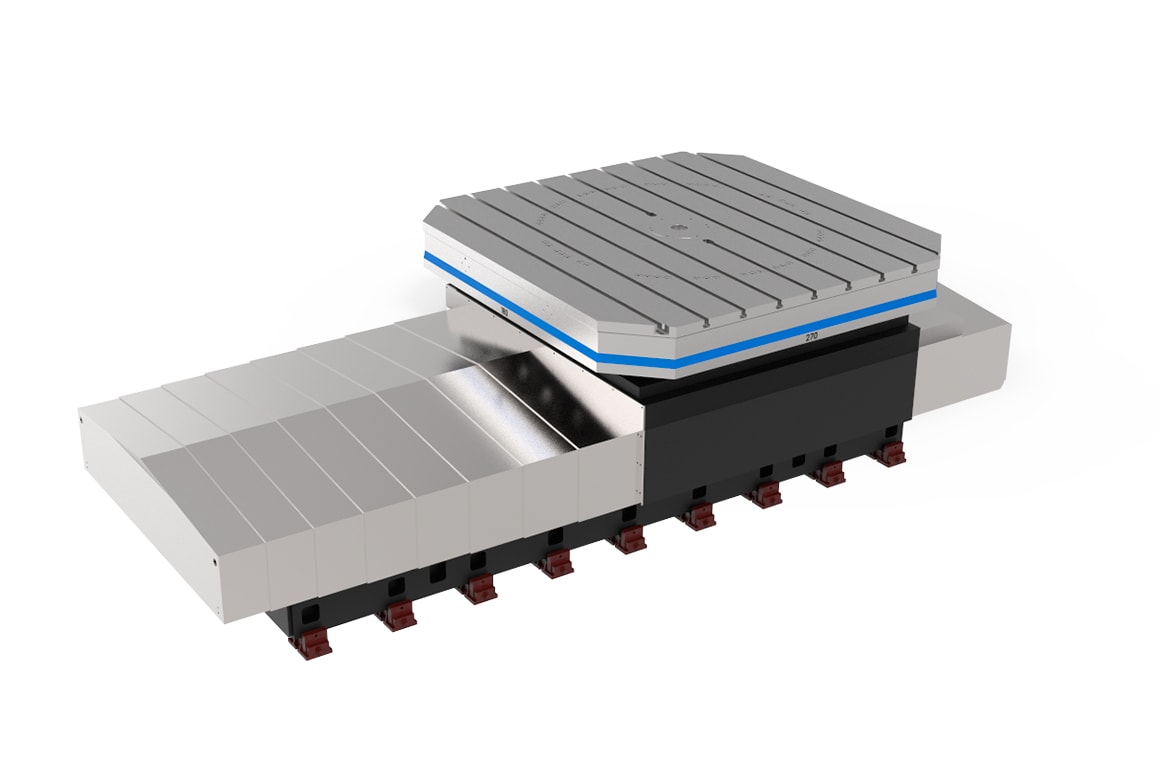

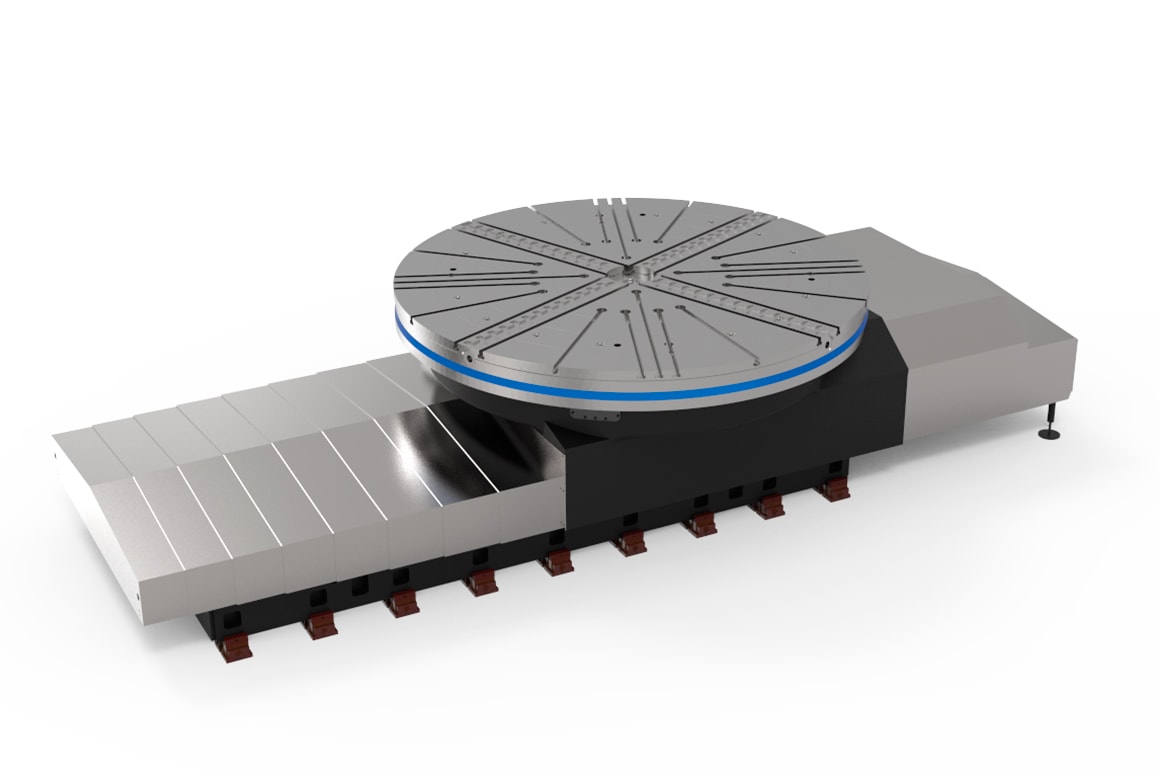

- Multitasking machine: milling and turning solution in a single set-up

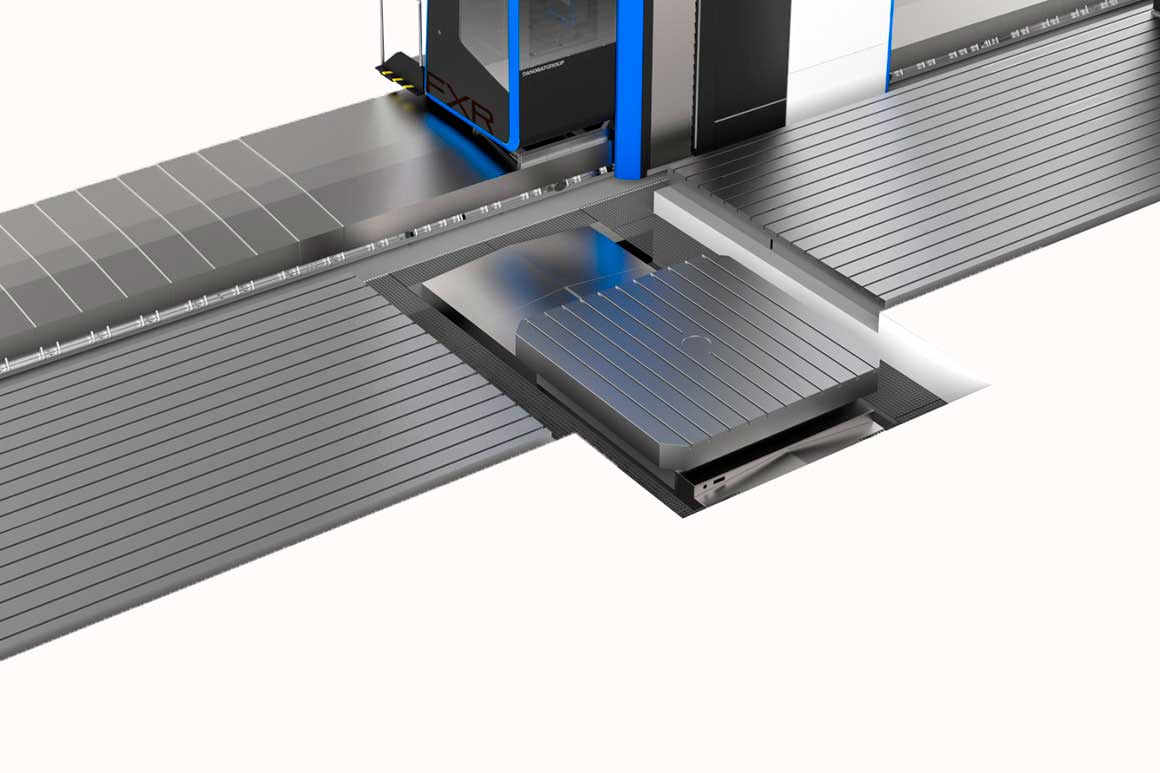

- Automated solutions: integrated palletised workpiece loading and unloading systems and robot-based solutions

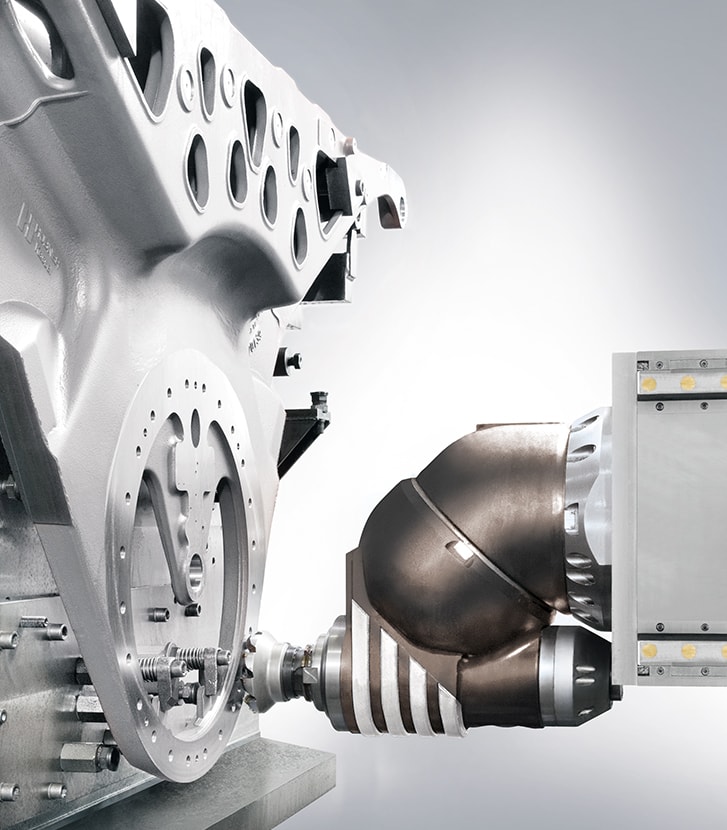

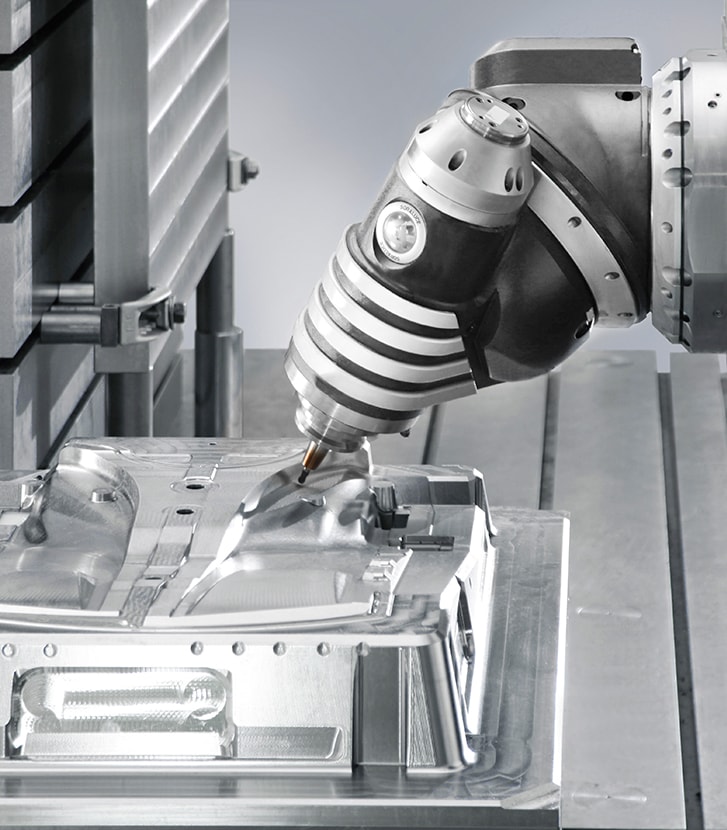

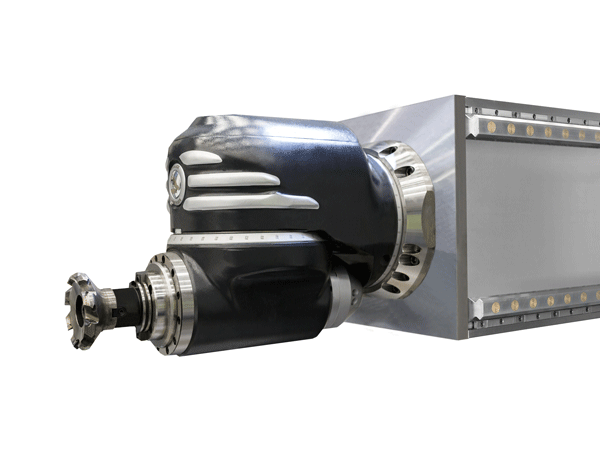

- SORALUCE head technology: highly reliable, extensive range of SORALUCE heads

- Automatic tool changing system

- SORALUCE Digital, Data System: comprehensive monitoring package with continuous information of machine and process status

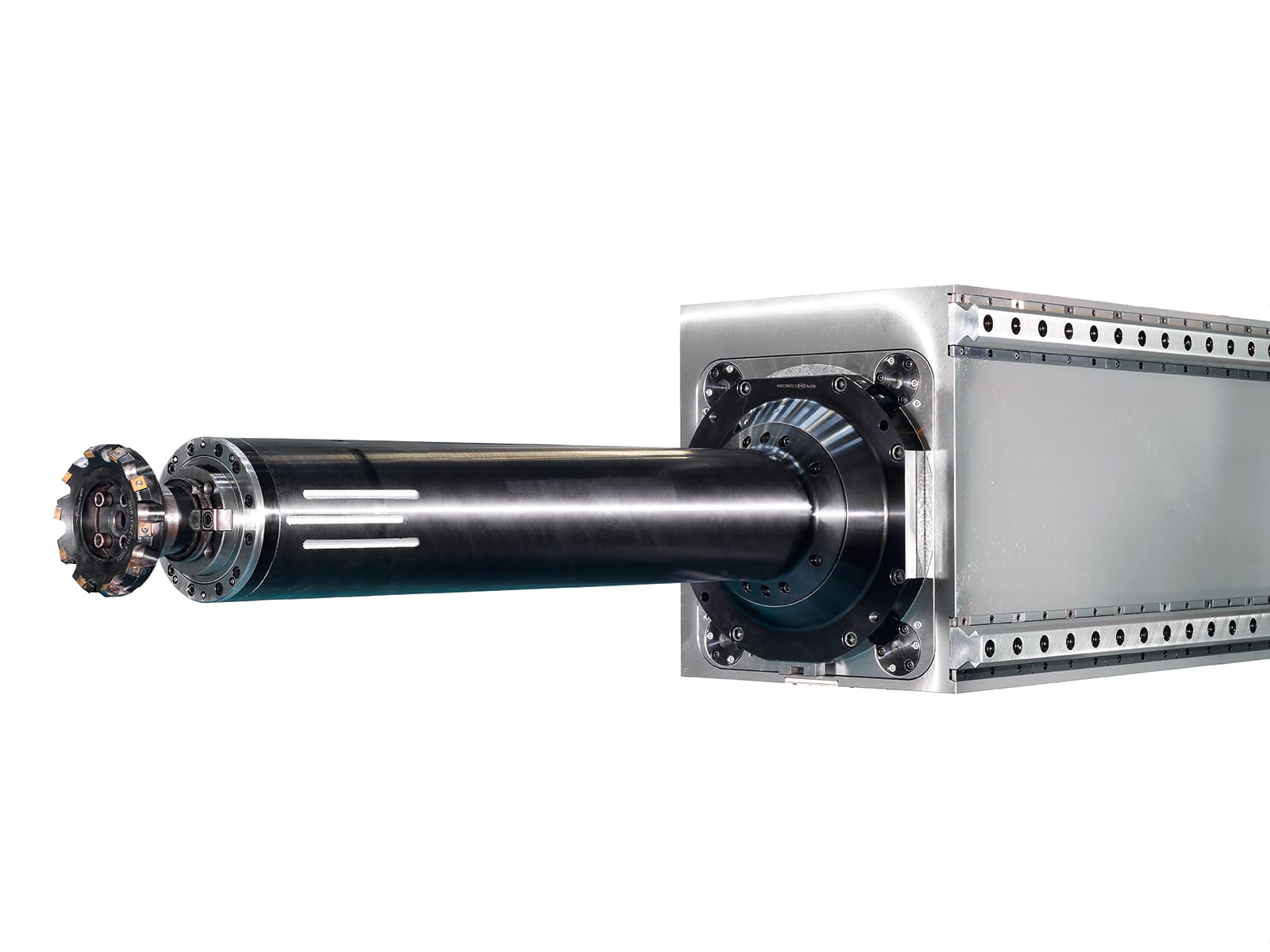

- Great precision and efficiency with the high-torque, direct drive spindle motor

- High dynamics with speeds of up to 35 m/min and acceleration of 2 m/s2

- Low gravity centre design providing improved stability

- Enhanced productivity and precision for components belonging to industrial vehicles, moulds and dies, capital goods and precision engineering industries

- Flexible machine architecture facilitating different machine configurations, the use of different work stations and pendulum machining

- Total machine concept design: complete working area analysed for optimal comfort, safety and ergonomics (maintenance spots, operator platform)

|

Characteristics |

FLP | |

|---|---|---|

|

Longitudinal traverse "X" axis |

mm |

3000 ÷ as per request |

|

Vertical traverse "Y" axis |

mm |

1800 / 2200 |

|

Cross traverse "Z" axis |

mm |

1300 / 1500 |

|

Spindle power |

kW |

37 / 43 |

|

Spindle speed range |

min-1 |

4000 / 5000 / 6000 / 7000 |

|

Rapid traverse |

mm/min |

35000 |

|

Tool magazine |

No. tools |

20 / 40 / 60 / 80 |

Customisation

Select your head:

Technical data

It enables for:

- Automatic indexing of vertical and diagonal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 43 / 46 / 55 kW

- 2.5° x 2.5° / 1° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 / 6000 / 7000 min-1

Technical data

Its compact design is specially conceived for machines with an in-line motor. It allows the simultaneous positioning of both head articulations, reducing non-production time.

Inverse machining capability:

- Up to -45º

- No additional setups

- Improved cycle time

- Better finishing quality

- Minimum manipulation

- Full advantage of machine travel

- No need for additional work piece support fixtures

- Close to table head spindle accessibility for both front and lateral milling

- 37 / 43 kW

- 1º x 1º

- 4000 min-1

Technical data

It enables for:

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system (no external tubes exposed to chips).

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- Flexibility

- Interchangeability

- Options

- C Axis

- Maintainability

- 43 / 46 / 49 / 81 / 106 kW

- 2000 / 3000 / 4000 / 5000 min-1

Technical data

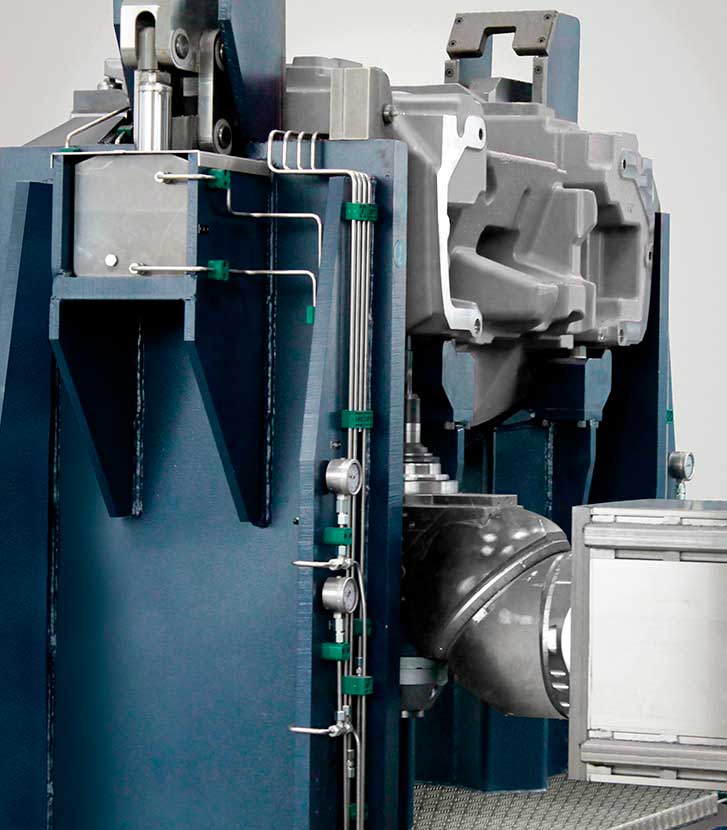

- Automatic indexing head with turning capabilities

- Up to 4000 rpm with standard steel bearings, or 5000 rpm with hybrid bearings

- Air-oil lubricated gears

- The head includes a clutch in the spindle area for positioning and clamping the spindle at any angle for turning operations. The clutch hydraulically clamps and unclamps the rotation of the spindle for turning operations

- Possibility of working with bigger diameter workpieces, performing turning operations in a diagonal direction (interpolation X/Z axes)

- The head can be positioned to avoid interferences with the workpiece

- The use of this head is highly recommended on multitasking machines (milling and turning)

- 37 kW

- 2.5° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 min-1