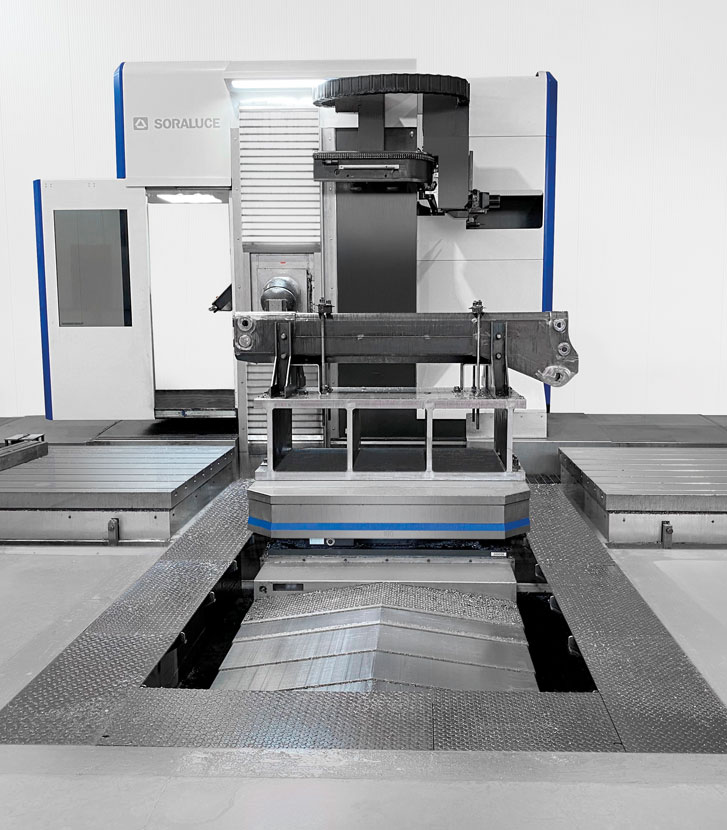

SORALUCE FA floor type milling boring machine

Performance Line. Born Reliable. Born Flexible.

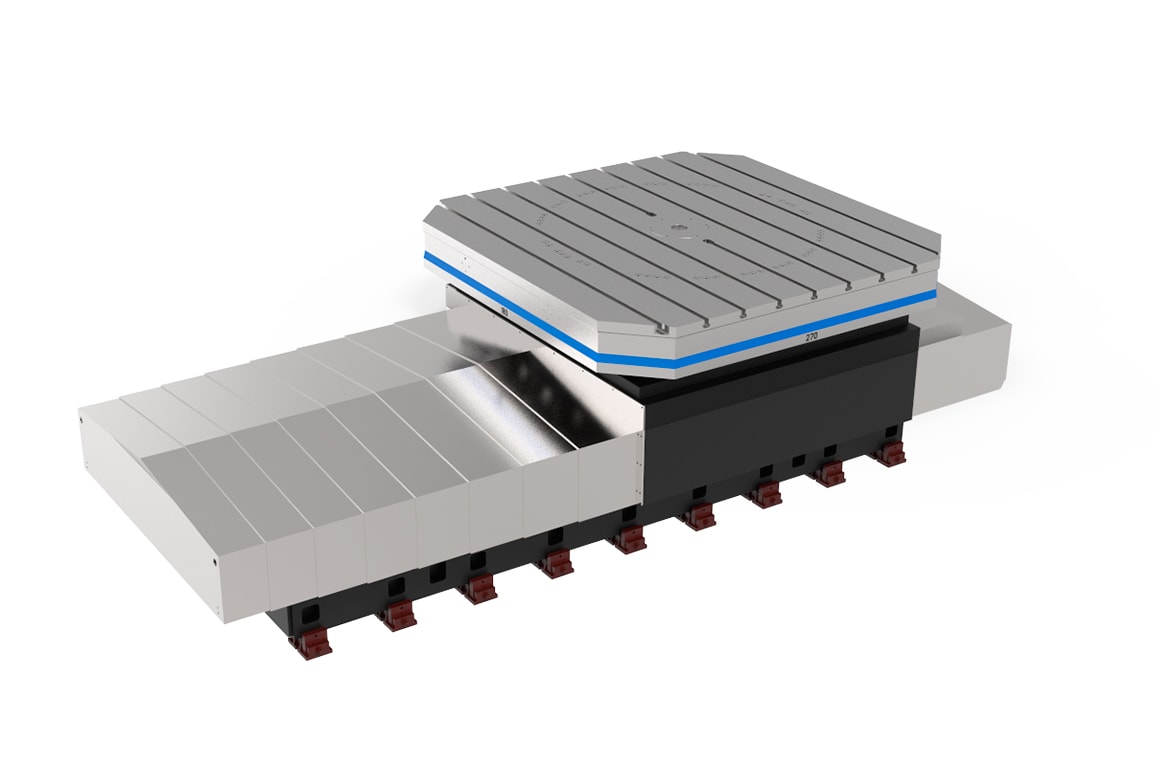

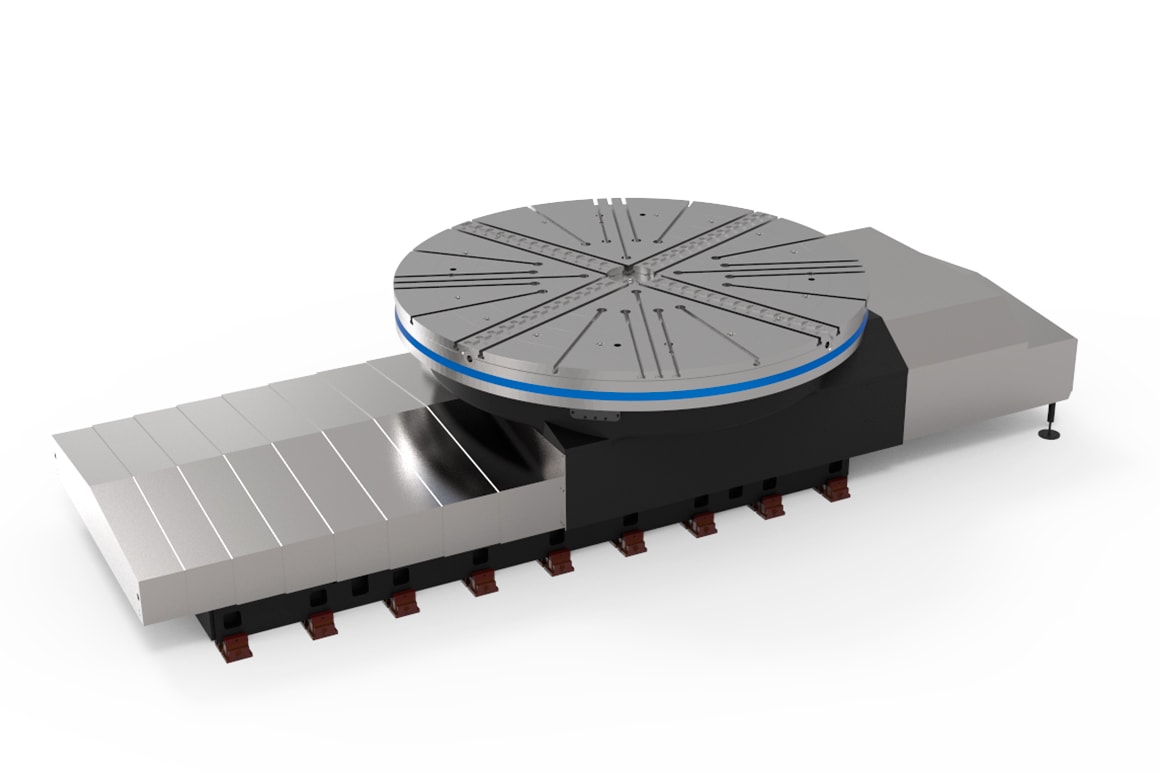

- High performance capacity in milling, turning and grinding in a single set-up.

- Much more than a machining center providing higher working volume, power, torque and cutting capacity.

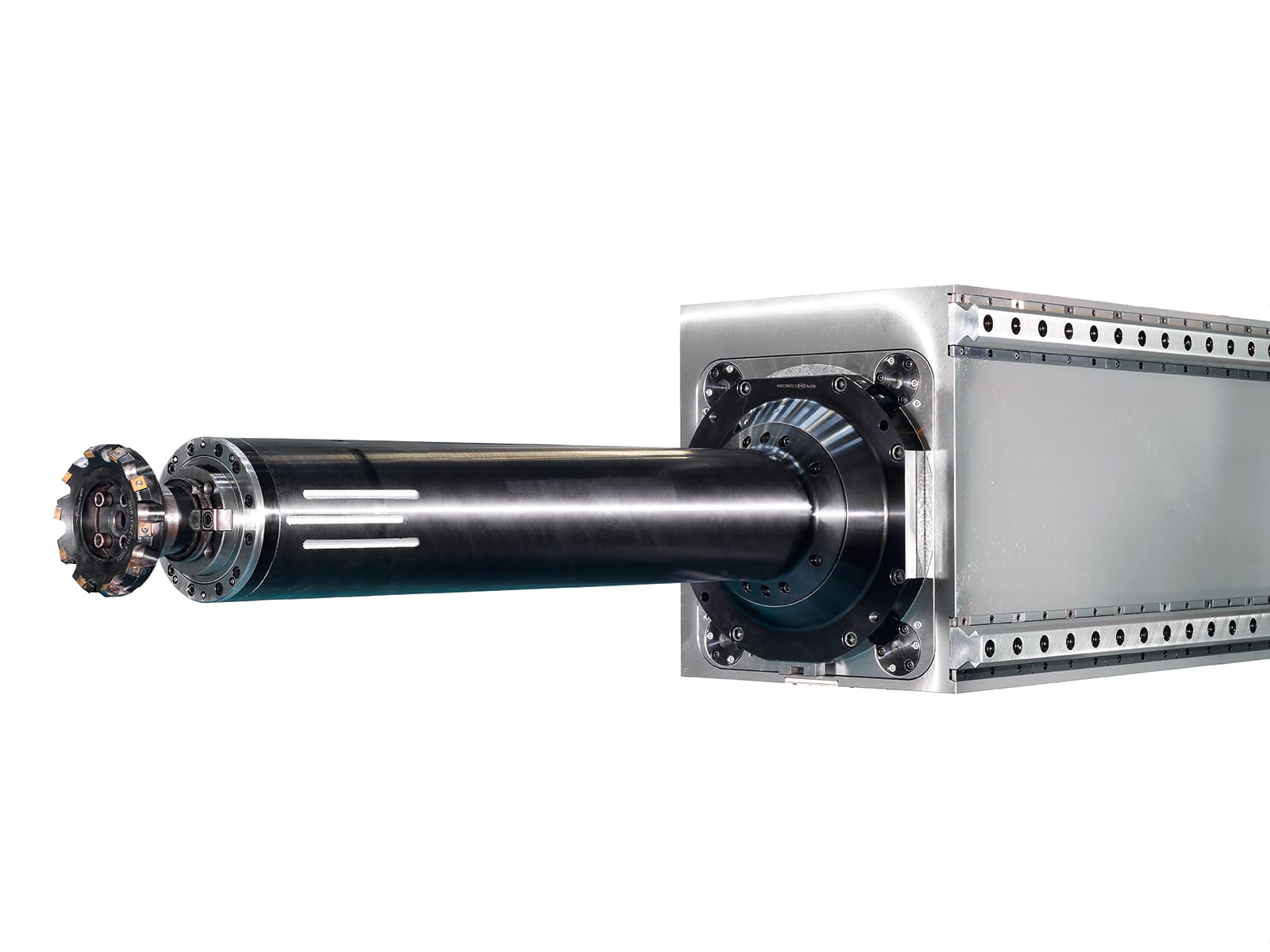

- Proven quality components: high performance 7000 rpm heads, direct drive inline motor and robust software.

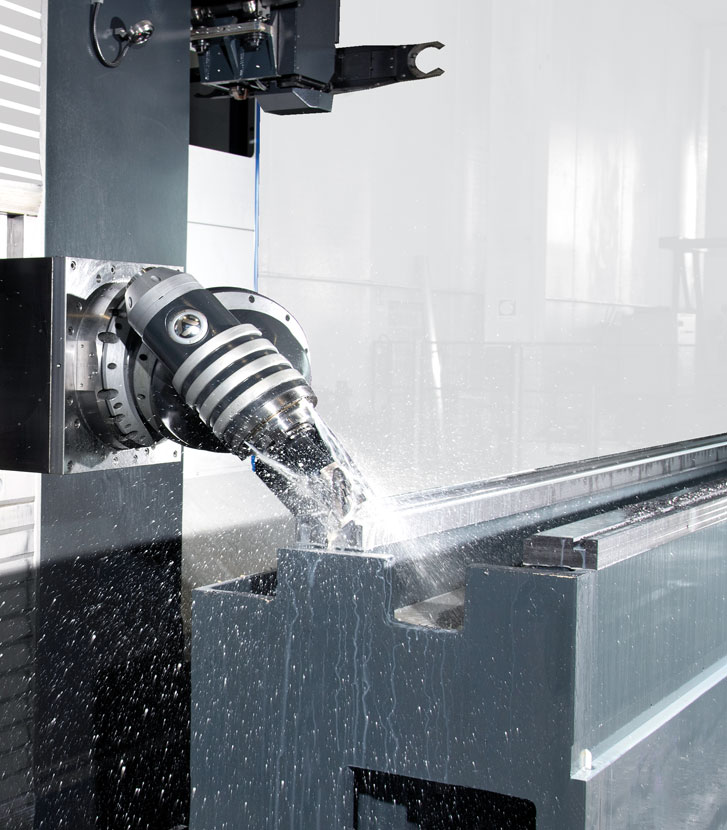

- Best geometric stability through water-based cooling and real time thermal compensation.

- Solutions adapted to your needs: New choice of milling heads with higher spindle speed and easy integration of milling & turning tables.

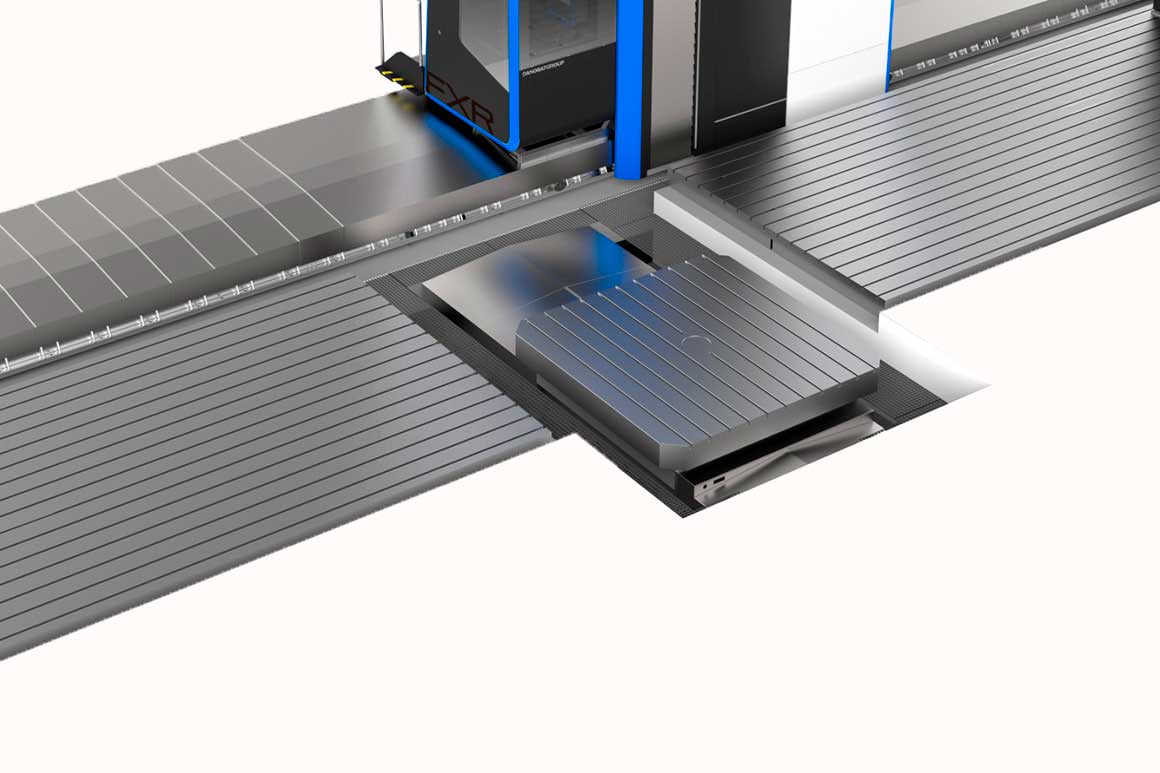

- Flexible machine architecture facilitating different machine configurations, the use of different work stations and pendulum machining.

- Set & Go: Less footprint in the workshop. Less expensive foundation. Easy transport & installation.

- Ergonomics & Easy maintenance.

|

Characteristics |

FA | |||

|---|---|---|---|---|

|

Longitudinal traverse "X" axis |

mm |

3000 ÷ as per request |

||

|

Vertical traverse “Y” axis |

mm |

1500 |

||

|

Cross traverse “Z” axis |

mm |

1200 |

||

|

Spindle power |

kW |

32 (S1) |

||

|

Spindle speed range |

min-1 |

6000 / 7000 |

||

|

Rapid traverse |

mm/min |

35000 |

||

|

Tool magazine |

No. tools |

40 / 60 |

||

Customisation

Select your head:

Technical data

- Automatic indexing head with turning capabilities

- Up to 4000 rpm with standard steel bearings, or 5000 rpm with hybrid bearings

- Air-oil lubricated gears

- The head includes a clutch in the spindle area for positioning and clamping the spindle at any angle for turning operations. The clutch hydraulically clamps and unclamps the rotation of the spindle for turning operations

- Possibility of working with bigger diameter workpieces, performing turning operations in a diagonal direction (interpolation X/Z axes)

- The head can be positioned to avoid interferences with the workpiece

- The use of this head is highly recommended on multitasking machines (milling and turning)

- 37 kW

- 2.5° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 min-1

Technical data

It enables for:

- Automatic indexing of vertical and diagonal articulations.

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system.

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- 32 / 43 / 46 / 55 kW

- 2.5° x 2.5° / 1° x 2.5° / 0.001° x 0.001°

- 4000 / 5000 / 6000 / 7000 min-1

Technical data

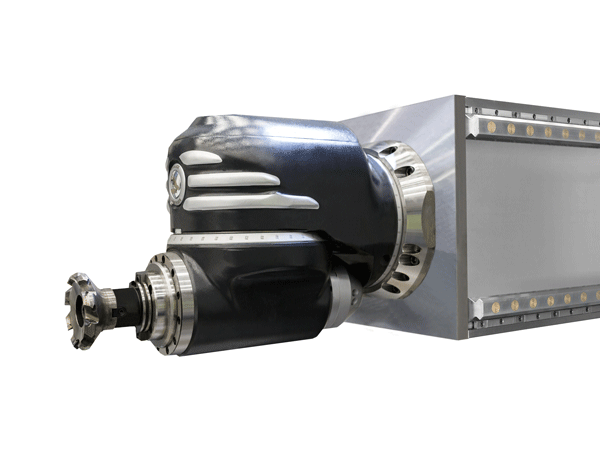

Its compact design is specially conceived for machines with an in-line motor. It allows the simultaneous positioning of both head articulations, reducing non-production time.

Inverse machining capability:

- Up to -45º

- No additional setups

- Improved cycle time

- Better finishing quality

- Minimum manipulation

- Full advantage of machine travel

- No need for additional work piece support fixtures

- Close to table head spindle accessibility for both front and lateral milling

- 37 / 43 kW

- 1º x 1º

- 4000 min-1

Technical data

It enables for:

- Automatic tool changing.

- Automatic head changing.

- Internal / external cooling system (no external tubes exposed to chips).

- Suitable for any type of taper and pull-studs.

- Different clamping forces for different tools.

- Suitable for setting different accessories.

- Flexibility

- Interchangeability

- Options

- C Axis

- Maintainability

- 43 / 46 / 49 / 81 / 106 kW

- 2000 / 3000 / 4000 / 5000 min-1